I-Servo icindezela, evame ukutholakala kuzilungiselelo zezimboni, idlala indima ebalulekile enqubweni yokukhiqiza ngokuhlinzeka ngokunyakaza okunembile nokuphindaphindayo. Kodwa-ke, ukuqinisekisa ukusebenza kwabo okuthembekile nokuvimbela noma yikuphi ukuphumula okungalindelekile, ukugcinwa kwansuku zonke kubalulekile. Lapha, sizohlola imisebenzi ehlukahlukene ehilelekile ekugcinweni kwansuku zonke kwama-servo press.

Ukuhlola Okubonakalayo

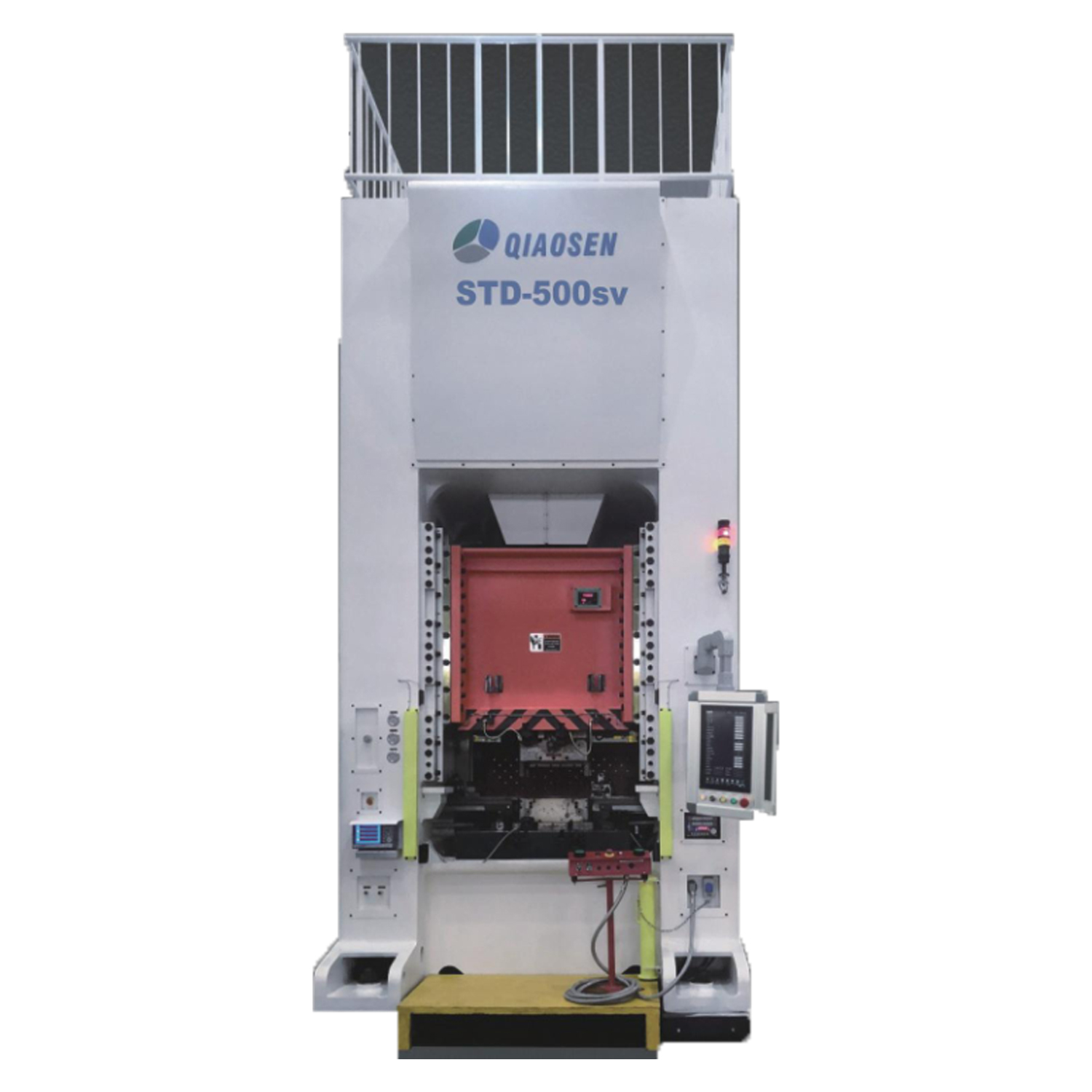

Isinyathelo sokuqala ekunakekelweni kwansuku zonke kweama-servo presswukuhlola okubukwayo. Lokhu kuhilela ukuhlola ngokucophelela umshini wokunyathelisa noma yiziphi izimpawu zomonakalo noma ukuguga. Izingxenye ezifana ne-servo motor, i-reducer, nesistimu yokuxhuma kufanele ihlolwe noma yikuphi ukungahambi kahle. Ukwengeza, uhlelo lokuthambisa, okuhlanganisa izindawo zokugcoba amafutha, kufanele luhlolwe ukuze kuqinisekiswe ukuthambisa okwanele.

Ihlola Isistimu ye-Servo

Uhlelo lwe-servo luyinhliziyo yomshini wokunyathelisa we-servo, futhi ludinga ukuhlolwa kwansuku zonke ukuze kuqinisekiswe ukusebenza kwalo okufanele. I-servo drive kanye nebhodi yokulawula kufanele ihlolwe noma yimuphi umonakalo noma izinto zangaphandle okungenzeka zifakwe phakathi kwezingxenye. Ukwengeza, ukuxhumana phakathi kwe-servo drive kanye ne-motor kufanele kuqiniswe ukuze kugwenywe noma yikuphi ukuxhumana okuxekethile okungase kuthinte ukusebenza komshini wokunyathelisa we-servo.

I-Lubrication Check

Ukuthambisa okufanele kubalulekile ukuze kugcinwe ukushelela nokusebenza kahle kokusebenza komshini we-servo. Izindawo zokuthambisa ezifana nama-bearings, bushings, kanye negiya kufanele zihlale zigcotshwa ukuze kuvinjelwe noma yikuphi ukungqubuzana noma ukubopha okungase kuthinte ukunemba nokusebenza kahle kokusebenza komshini. Isibhamu samafutha kufanele sibhekwe ukuthi akukho yini ukuvaleka noma ukuvuza ukuze kuqinisekiswe ukugeleza okufanele kwamafutha kuzo zonke izindawo zokuthambisa.

Ukulinganisa Kwansuku zonke

Ukulinganisa kwansuku zonke kubalulekile ukugcina ukunemba nokuphindaphinda kokusebenza komshini we-servo. Ukulinganisa kuhlanganisa ukuhlola ukunemba kwesikali sesishumeki, inzwa yokucindezela, nenzwa yokugudluza ukuze kuqinisekiswe ukuthi zifunda ngokunembile. Ukwengeza, ibhalansi yasentwasahlobo kufanele ihlolwe ukuze kuqinisekiswe ukuthi ilungiswe kahle ukuze inikeze ukulawula kwamandla okunembile ngesikhathi sokusebenza kwabezindaba.

Ukuhlanza Nokunakekela

Ukuhlanza nokugcinwa njalo kubalulekile ukuze kugcinwe ukusebenza kahle nokuphila isikhathi eside kwemishini yokunyathelisa ye-servo. Umshini wokunyathelisa kufanele uhlanzwe njalo ukuze kukhishwe noma yiziphi izinto zangaphandle noma imfucumfucu okungenzeka inqwabelene phezu kwawo noma ngaphakathi kwezingxenye zawo. Izingxenye ezifana nohlelo lokuxhumanisa nama-bearings kufanele zihlanzwe futhi zihlolwe njalo ukuze kutholakale noma yikuphi ukunqwabelana kwemfucumfucu okungase kuthinte umsebenzi wazo.

Ekuphetheni, ukugcinwa kwansuku zonke kwemishini yokunyathelisa ye-servo kuhilela ukuhlolwa okubonakalayo, ukuhlola uhlelo lwe-servo, isheke lokugcoba, ukulinganisa kwansuku zonke, nokuhlanza nokugcinwa. Ukwenza njalo le misebenzi kuzoqinisekisa ukusebenza okuthembekile nokuphila isikhathi eside kwemishini yokunyathelisa ye-servo, okuholela ekusebenzeni okuphumelelayo nokunembile kokukhiqiza.

Isikhathi sokuthumela: Oct-16-2023